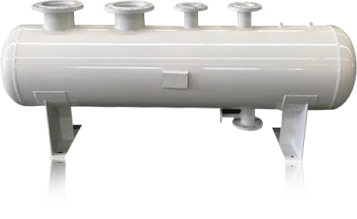

The sub-cylinder is also called the sub-drum, which is the main supporting equipment in the steam boiler. It is widely used in power generation, petrochemical, steel, cement, construction and other industries. It can distribute the steam generated by the boiler to various pipelines. The pressure-bearing equipment of the sub-cylinder system belongs to the pressure vessel, and its pressure-bearing capacity and capacity should correspond to the supporting boiler. The main pressure components of the sub-cylinder are: head, shell material, etc.