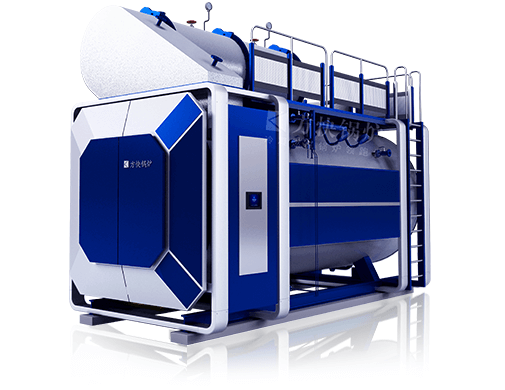

The closed condensate recovery system is combined with the three-pass structure, economizer and air preheater to fully utilize the heat of the gas or oil, and the heat of the high-temperature condensate is recovered from the source, which can save operating costs and improve boiler operating efficiency.

Get a quote

The closed condensate recovery system can recover more than 70% of condensed water, saving the overall operating cost of the boiler for the enterprise.

Using the crossing wine-shape heat transfer technology, the heat transfer area is increased by 5 times, saving 2/3 of the floor space compared with the ordinary boiler.

The combustion is deep matched to the heat exchanger, breaking the limits of the burner, and the boiler becomes a complete thermal energy system, further improving efficiency.

Through parallel combination, multi-machine joint control can be completed, and up to 128 boilers can be controlled at the same time.

The waste heat recovery device comprises an economizer and a condenser, and the heat exchange is realized by using flue gas and water. The material of the silicon-aluminum alloy used in the crossing wine-shape fire tube, has good corrosion resistance and durability.

The fan controlled by frequency conversion has more adjusting intervals, the combustion adjustment is more elaborate, and the boiler runs more smoothly under different working conditions.

| Types | Evaporation | Steam pressure | Steam temperature | Feed water temperature | Thermal efficiency | Fuel | Natural gas consumption | Power requirement | Electric power | Length * Width * Height | Weight | Chimney |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Unit | t/h | MPa | ℃ | ℃ | % | Nm3/h | V/Hz | KW | mm | t | mm | |

| θ5-2800 | 4 | ≤1.6 | 204 | 150℃(80%) 20℃(20%) |

>95 | Natural gas | 250.4 | 380/50 | 29.5 | 5000 * 2500 * 4200 | 13 | 700 |

| θ5-4200 | 6 | 375.6 | 48 | 5700 * 2500 * 4400 | 18 | 900 | ||||||

| θ5-7000 | 10 | 625.3 | 60 | 7100 * 4700 * 5000 | 28 | 700 | ||||||

| θ5-10500 | 15 | 937.9 | 77 | 7300 * 5400 * 5500 | 39 | 900 | ||||||

| θ5-14000 | 20 | 1250.6 | 120 | 7600 * 5800 * 6000 | 56 | 900 |