Higher thermal efficiency

By adopting advanced technologies such as condensation recovery, the latent heat and sensible heat in the high-temperature flue gas generated after combustion are fully utilized.

In the same operating environment, the thermal efficiency of gas-fired boilers can reach more than 98%. Compared with other fuel-type boilers, the input cost can be reduced by at least 10% in one year.

Higher level of automation

The gas boiler is equipped with a DCS control cabinet and a PLC intelligent control system. By operating the control system, boiler start-up, shutdown, and temperature and pressure adjustment can be completed.

The degree of automatic operation of gas boilers is so high that it can also reduce labor costs. Under normal circumstances, only one furnace person can be equipped with one boiler.

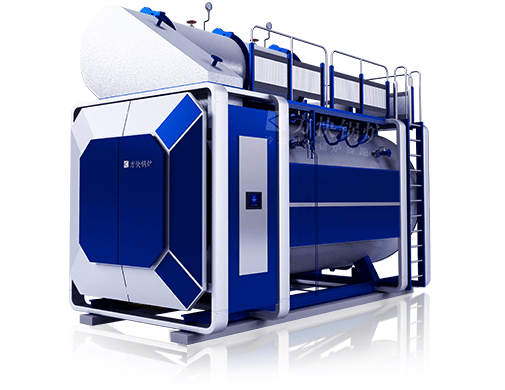

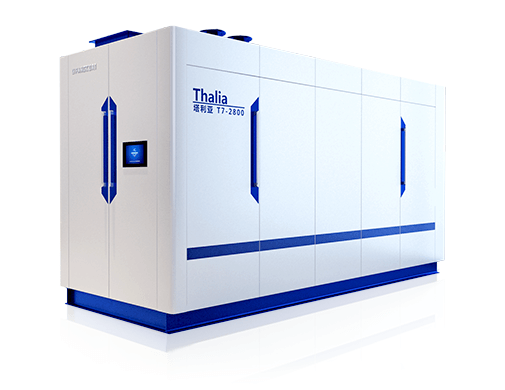

Smaller footprint

After many tests and adjustments, the gas boiler body, combustion system and pump piping and other accessories have been organically combined to become a more unified whole.

Compared with the traditional boiler equipment on the market, the gas boiler directly reduces the overall volume of 20-40% under the premise of ensuring the same function, and also reduces the capital cost of the boiler room.

Lower pollutant emissions

Gas-fired boilers use one of the world's cleanest energy sources, gaseous fuels, which do not produce ash or slag, and other pollutants are emitted infrequently.

Gas-fired boilers are fully in line with the global sustainable development strategy, and are also promoted by many governments. Even some governments provide project subsidies and incentives (such as China) for units that use gas boilers.

Longer service life

As a special equipment with pressure, the gas boiler is necessary to achieve the ultimate safety measures. The fluctuations of various parameters such as temperature, pressure, power supply, scale, water level, etc. will be fed back to the control system through real-time monitoring software. Once the controllable range value is exceeded, the alarm system will be activated immediately.

In general, after regular and appropriate maintenance measures for gas boilers, the service life of the boiler can be as long as 15 years or even 20 years.

Better operating environment

In the project site of the gas boiler, only the fuel delivery pipeline needs to be set up, and there is no need to open a separate site for storing fuel, which can also reduce part of the investment cost.

The boiler is fully automatic, noise-free and dust-free. Not only does the boiler have a good operating environment, but it also provides a comfortable working environment for the operator.